How an AGA Refurbishment Works from Start to Finish

Refurbishing an AGA gives you the performance of a new cooker while retaining its original charm.

It is ideal for older models that still have solid cast iron foundations but need fresh enamel, insulation or an upgrade to a modern fuel system.

Here is how the process works from start to finish.

1. Initial Assessment

The process begins with a full inspection. An engineer will check the condition of the enamel, castings, insulation and internal components.

This helps identify what needs replacing or upgrading. If the cooker is still in place, it can often be assessed before dismantling so you know exactly what to expect.

2. Dismantling

The AGA is carefully dismantled piece by piece. Doors, lids, hotplates and enamel panels are removed and labelled.

The internal insulation is taken out, and the cast iron ovens are separated from the main frame. This stage also allows the engineer to inspect parts that are normally hidden, such as brackets, rods and insulation channels.

3. Cleaning and Preparation

Each section is cleaned thoroughly to remove carbon, grease and surface corrosion. The cast iron parts are then prepared for re-enamelling or refinishing. Any damaged or worn components, such as hinges, seals or washers, are replaced with new parts.

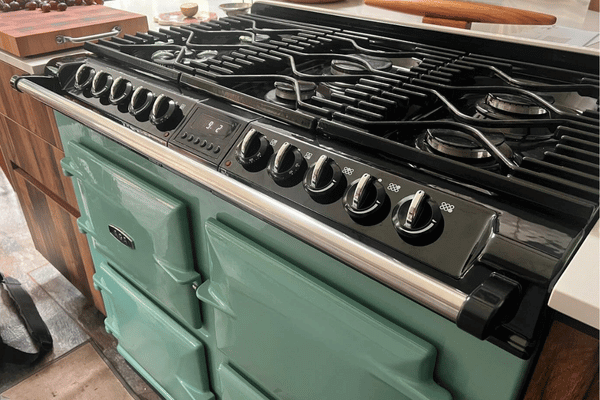

4. Re-Enamelling

The enamel panels are refinished using high temperature vitreous enamel. This involves applying powdered glass to the cast iron and firing it at extreme heat to fuse the two materials.

The result is a smooth, glossy and durable surface that resists stains and heat. At this stage, you can choose a new colour or match the original finish.

5. Insulation Renewal

Old insulation is removed and replaced with fresh vermiculite and thermal blankets. This dramatically improves efficiency, reducing heat loss through the top and sides of the cooker. Proper insulation is key to maintaining steady oven temperatures and lowering running costs.

6. Reassembly

Once all parts are cleaned, enamelled and insulated, the cooker is rebuilt. Each section is carefully aligned to ensure even heat distribution and a tight seal around the ovens and hotplates.

New door seals, washers and chrome fittings are installed to complete the finish.

7. Fuel System or Electrical Work

Depending on your setup, this stage includes fitting a new burner, gas system or electric conversion.

Modern electric conversions allow individual ovens and hotplates to be controlled separately for better efficiency.

8. Testing and Final Checks

Before completion, the cooker is fully tested. Engineers check oven temperatures, heat distribution and safety systems. Only once everything is working as it should is the refurbishment considered complete.

The Result

A refurbished AGA performs just like new but often with better efficiency and insulation than the original build. You can keep your existing model, choose a fresh colour and enjoy reliable performance for many more years.

Smart Range specialises in full refurbishments, re-enamelling and electric conversions across Surrey, Kent, Sussex and London. Contact us to discuss restoring your AGA or to request a quote.